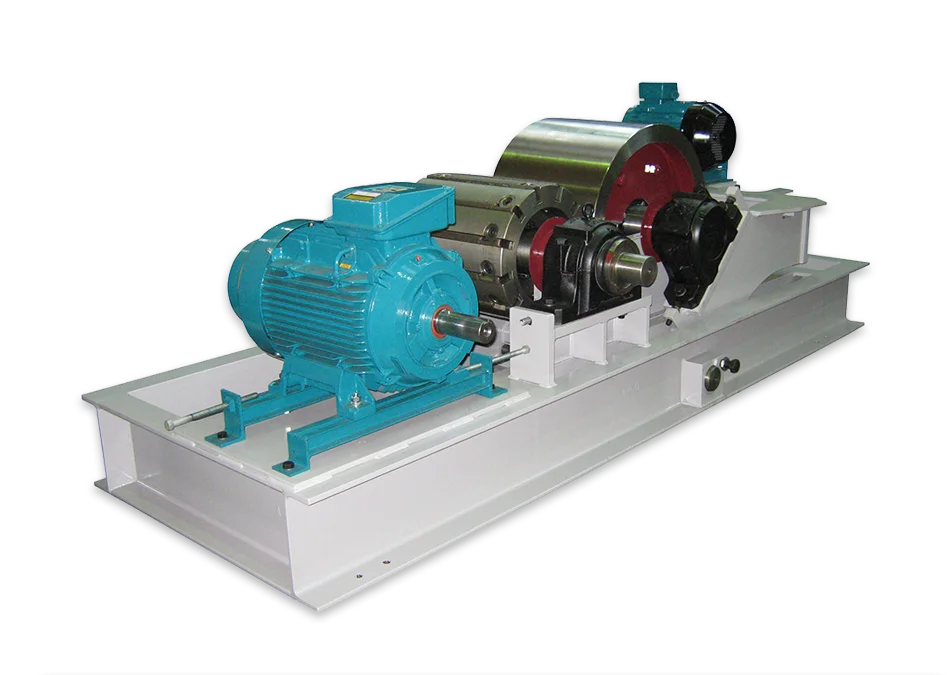

Disintegrators

- ‘D’ Series machines to reduce medium/soft clay, moist clays and shales.

- Possible alternative to wet or dry grinding mills where the material is friable and does not require working.

- Fitted with large slow roll with smooth renewable shell.

- Pivoted small fast roll with renewable hardened breaker bars.

- Easily adjusted roll gap setting system.

- Heavy-duty spring-loaded machine protection.

- Three sizes of machine available, 500mm, 800mm & 1000mm wide.

- A feed size of 100 – 150mm is accepted with an output down to 2mm (depending on gap and bar setting).

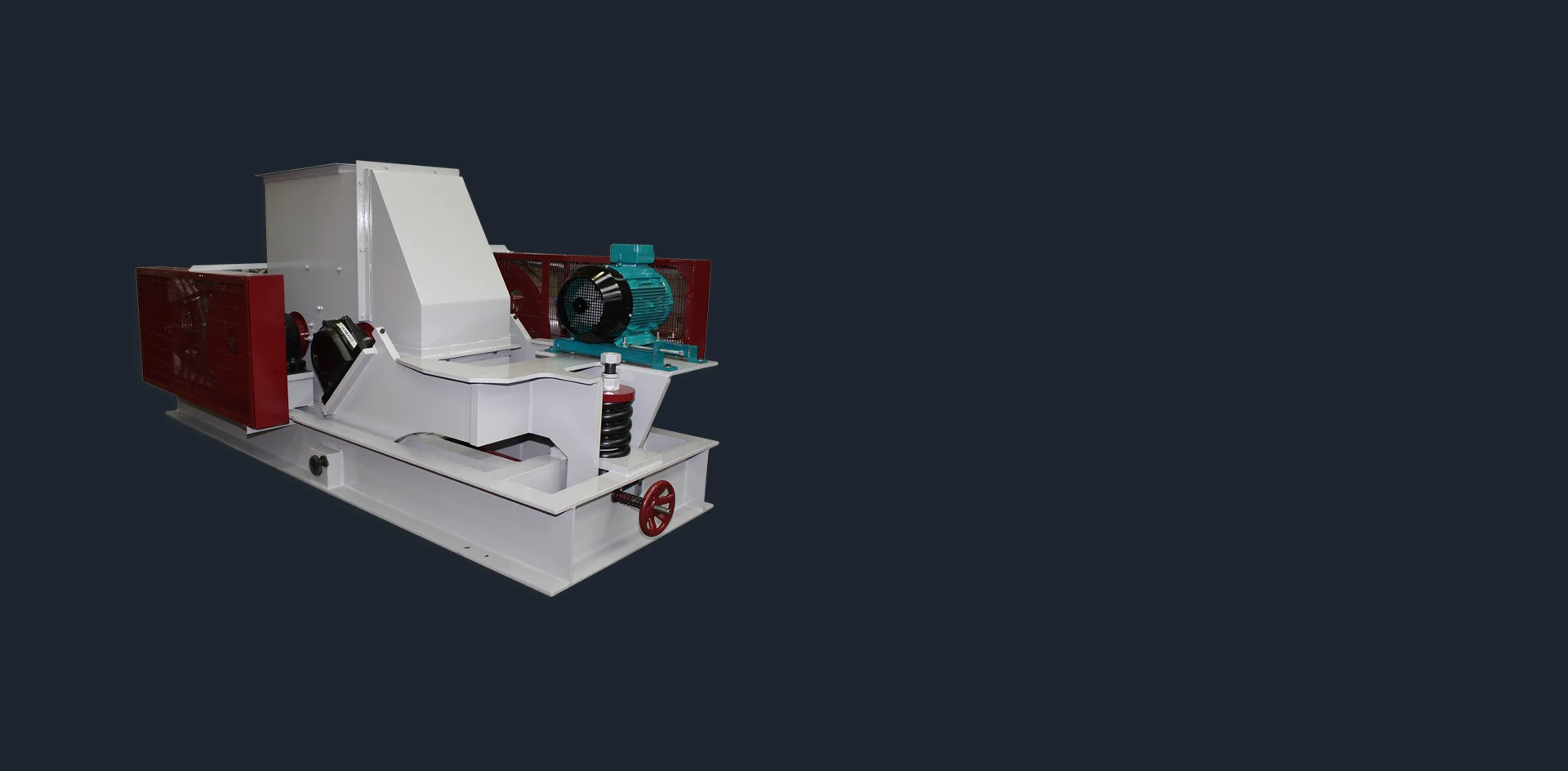

Hammer Mills

- Can complement or replace traditional dry grinding mill(s).

- Handles materials in the range of 8-12% moisture content (wet basis testing).

- Feed size 200mm maximum (for best results feed at an even rate).

- Screen bars available with variable spacing to offer variable size output.

- Final particle sizing by high speed rolls or vibrating screen to suit requirements.

- Two HM900 & HM1100 models of double rotor design available.

- Other single-rotor models are available on request.

Specification

- Product Type

M/c Size

D500 D800 D1000

Material Input (mm)

Up to 150

Max Material Output (mm)

Variable down to 2 to 3

Throughput (T/ Hr)

20 to 50 30 to 80 50 to 100

Power (kW)

7.5 & 37 7.5 & 55

M/c Size

HM 900, HM 1100

Material Input (mm)

Up to 200

Max Material Output (mm)

Variable down to 1

Throughput (T/ Hr)

Up to 60, Up to 90

Power (kW)

2 x 75, 2 x 100